November 11, 2015 | Smart Manufacturing

3 Things about the Value Chain You’ll Kick Yourself for Not Knowing

Michael Porter is the founder of the value chain concept, which was developed in 1985 through competitive advantage. Its primary focus is to allow an organization’s resources to outperform those of its competitors.

Michael Porter is the founder of the value chain concept, which was developed in 1985 through competitive advantage. Its primary focus is to allow an organization’s resources to outperform those of its competitors.

What Does “Value Chain” Mean?

The value chain is a combination of nine generic value added activities that operate within an organizationand work together to provide value to customers.

The value chain is where business management

and manufacturing meet.

#1: A Value Chain Works in Reverse to a Supply Chain

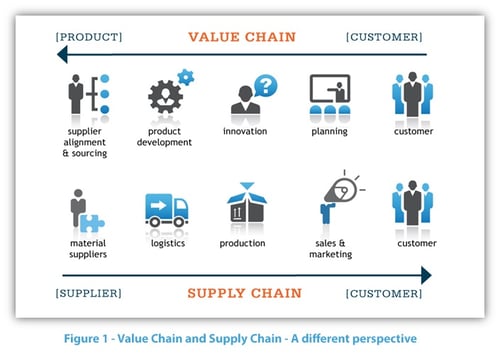

A supply chain starts from the inside and flows outward to the customer. It starts with materials and suppliers then continues on to logistics and production. Finally, it ultimately reaches sales, marketing and the customer.

Contrary to this, the value chain starts with the customer and flows inward to supplier alignment and sourcing. You can see the difference between the value and the supply chain flows below:

As you can see, both chains are closely related; the value chain flow is essentially a re-ordered version of the supply chain flow, which offers a different perspective to management.

Researcher Andrew Feller says:

“Supply chains focus upstream on integrating supplier and producer processes, improving efficiency and reducing waste, while value chains focus downstream, on creating value in the eyes of the customer.”

#2: Value is Perceived by the Customer

Since the value chain flows from the customer first, the value of a product or service is perceived by the customer.

If the customer does not perceive value in the supply chain, there will be no demand for the product. Likewise, if the supply chain is unable to deliver resources that the customer values, at the right price, then there will not be a flow in the value chain.

#3 Use Smart Manufacturing to Create a Fluid Value Chain

It can be difficult for an organization’s manufacturers and suppliers to adjust the customer’s added values in real-time.

Using smart manufacturing strategies can help people in those roles collectively integrate a set key of performance indicators, which can enhance the values perceived by customers. Collaboration from the suppliers is then needed to address manufacturing and process performance issues throughout the system.

Smart manufacturing, through collaborative efforts, benefits the supplier’s path of communication and the fluidity of the value chain.

Bringing it All Together

The desired outcome of all this is to use the most efficient methods available to produce a product that is in demand. Michael Porter developed the concept of a value chain and how it focuses on the customer’s perceived value--gauging value on an inward path to make the supply chain better every step of the way.

In contrast, the supply chain focuses on material and suppliers and works its way out to put the parts together to create a product. It focuses on a forecasted value perceived by customers, rather than an actual value perceived by customers.

The process of the value chain, customer perception of added value and incorporating a smart manufacturing strategy for your organization are just a few things about the manufacturing value chain you should know.

Leave a Comment