November 5, 2015 | Lean

Lean Manufacturing: Basic Fundamentals to Consider

Lean manufacturing can be traced back to Taiichi Ohno’s production system at Toyota, and has been gaining traction ever since. The practice of lean manufacturing is well known for eliminating the waste from manufacturing processes, resulting in more efficient and sustainable systems.

Lean manufacturing can be traced back to Taiichi Ohno’s production system at Toyota, and has been gaining traction ever since. The practice of lean manufacturing is well known for eliminating the waste from manufacturing processes, resulting in more efficient and sustainable systems.

The purpose of this post is to highlight a few of the fundamental components of lean that are important to remember when considering a lean manufacturing implementation.

5 Lean Principles

Lean manufacturing is founded on guiding principles representative of lean culture. The five fundamental principles of lean manufacturing are:

1. Understanding value as defined by the customer

This simply means that customers need to be able to define the value (the specific benefits) a given product will provide.

2. Defining the value stream for the organization

In short, you should be able to define and create value without waste.

3. Establishing continuous flow within the organization

Streamline value-added processes throughout the workflow within your organization.

4. Maintaining the flow throughout the use of a pull system

Implementing a pull system means allowing the customer to pull value from the product.

5. Pursuing perfection through continuous improvment of the processes

Quality should be actively pursued and make imperfections visible.

Lean principles are designed to improve competitiveness and customer satisfaction. These five principles should be satisfied when implementing a lean system.

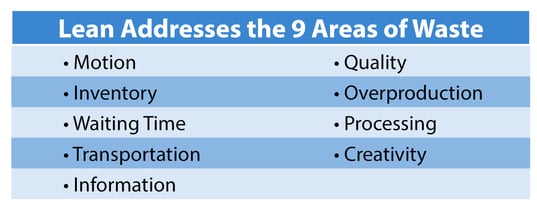

The 9 Mudas

MUDA is a Japanese term that means "waste." Lean is about eliminating waste in the manufacturing process. There are 9 areas of most commonly identified “fatty” areas, or MUDAs, in traditional manufacturing systems:

Lean implementation must satisfy the five Principles of Lean and is necessary to address the nine key areas of waste. These principles are designed to insure that the improvements are customer-centric, solve critical waste issues and can be sustained.

Lean or 6 Sigma?

Lean and six sigma ideology are fundamentally interchangeable, because both are directly involved with reducing waste and product defects. Arguably, Six Sigma is considered the overarching discipline, with lean being subordinate to it. Either way, when lean manufacturing and six sigma are applied properly, the desired outcome should be the same. Here you can read more about the key elements of six sigma.

Never Ending

Lean manufacturing is not something that you stop using once improvements are seen or the systems are implemented; lean is an ongoing process your company can use to continually see improvements in:

- Stock turnover

- Efficiency

- Profitability

- Employee morale

- Inventory

- Machine performance

- Delivery

- Supplier relations

The Tools

Lean manufacturing is implemented by specific MUDA resolving tools. Some lean tools that CMTC offers are:

- Value Stream Mapping: illustrates current and future states

- Kaizen: involves a process for improvement of events

- Simulation: provides a hands-on learning approach of key principles

- 6S: focuses on organizing work space to reduce waste and improve safety

- Visual Factory: displays notifications for rapid response

Quick Tips

- Concentrate on poor processes, not people. Having respect for the employees in an organization fosters a culture of trust and empowerment, which in-turn helps solve problems.

- You’ve gone through consultations and have created an optimal lean strategy for your organization- now follow through with it.

- Lean strategies are consistently changing and updated, and, sometimes, conventional ideologies can become outdated. Welcome and encourage the development of fresh perspectives from your team.

For more quick tips on lean manufacturing, click here.

Lean Food for Thought

Building a lean culture is not limited to just the production line. It is applied from the office workspace through production and distribution. The lean strategies and visions for an organization need to be clearly communicated in order for lean cultural changes to occur. Also, remember that lean is an ongoing process and that it takes time; sometimes lean goals can be reached in a matter of weeks, but most are reached after a few months if there is a company wide acceptance of cultural change.

If you need more direction or a consultation on how lean can be implemented in your organizations, you can click here.

Leave a Comment