January 17, 2017 | Manufacturing Technology

How to Determine If a New Technology Is Worth the Investment

The latest and greatest new technology is something that many of us are prone to want – not just for the workplace, but for the personal aspects of our lives.

The latest and greatest new technology is something that many of us are prone to want – not just for the workplace, but for the personal aspects of our lives.

The newest generation of smartphones, for example, is something many consumers buy simply because it’s the latest model. However, what you may notice in the latest generation of a model is that certain features or designs revert back to previous generations.

The company making the model got the message from consumers that previous characteristics were preferable. So, when determining whether or not a new technology is worth the investment, it’s worth carefully weighing the possible pluses and minuses.

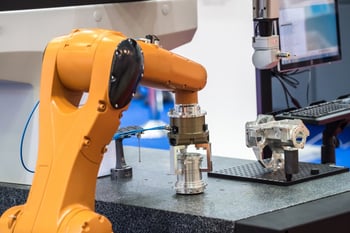

An eyebrow-raising trend in recent years is a new and increasing feature on shop floors – use of robotics. While automation is a significant factor saving manufacturers and non-manufacturers alike on labor costs, advancements in robotics also have been proving to be a cost-effective tech measure with physical production.

While the majority of manufacturers in the U.S. are modest in size, investing in new tech such as advanced robotics, as well as recent achievements in artificial intelligence, may or may not be the way to go.

Some business leaders may approach such a decision similarly as a personal purchasing decision. Of course, buying for the betterment of the company is a very different dynamic. Rather than simply sizing up hardware, software, CRM systems or machinery, consider the following criteria if the balance of investment pushes the needle forward.

Is It Intuitive?

Let’s say you’ve figured out that, once up and running and your people have fully integrated the new tech in their workflow, it’s worth the investment. However, beforehand, It’s worth asking, how long it will take to get to that point. How many work hours will you have to sink into training for the new technology?

Revisit or implement your company’s cost-benefit analysis, your systematic approach to estimating the strengths and weaknesses of new tech. Sometimes, an investment data-collecting AI, for example, can improve your measurements of Key Performance Indicators (KPIs).

Not only do you have to budget finances for new technology, you also have to budget time for training.When Can You Realistically Integrate It?

Not only do you have to budget finances for new technology, you also have to budget time for training. If you wait too long, the edge you were hoping to get with the new system may dwindle. Tech moves fast these days.

Be Exact with Its Utility.

Clearly identify what it is that will make you and your people’s workflow more productive. Perhaps more importantly, make sure that the person using new software, for example, is able to see the positive in it. A CRM program is often underused because workers see only the negative. Another utility may be something very different but equally valuable, such as a drastic increase in energy efficiency.

Does It Add Value to the Customer?

Remember that increased productivity is easy to define – getting more with less. When evaluating new technology, how will it get you ahead with metrics that matter? Often, new tech will promise all kinds of new benefits, but are they benefits that really matter to your consumer? It’s up to decision-makers to figure out any new benefit will ultimately lend itself to the consumer.

Measure Efficiency.

Does the new tech speed up processes – either on the shop floor, in administration or management? There’s another way to think about speed – does it make your people understand things better and faster? Some software or tech gadgets have the ability to do the work of conceptualizing projects or the big picture of the business.

Think Long-Term.

It’s understandable that there will be a learning period. However, try to imagine ease of use after you and your people are sufficiently trained. New tech will have new features that may unexpectedly eat up time.

All in all, make sure you are very clear as to how new technology is worth the investment for your company. The more benefits you can check off without having second thoughts, the better.

Leave a Comment