December 5, 2015 | Manufacturing Technology

4 Trending Topics in Manufacturing Technology

The manufacturing industry has been making rapid advancements and paving the way for innovative and cutting-edge technologies. With more precise control over innovative machinery, manufacturers are able to sustain efficient methods and create higher quality products. Being able to use machinery that have sensors programmed into them gives manufacturers the ultimate process control.

Trending Now

Innovative technologies have been introduced and implemented in the manufacturing industry from washing machines and dishwashers to computers and printing processes. Below are some recent and future innovative technologies trending within the manufacturing industry.

1. 3D (Three-dimensional) Printing

Now, a simple digital file can form three-dimensional structures layer-by-layer. This innovative manufacturing technology has progressively become more advanced over the past couple of decades, transforming the methods manufacturers use to create structures.

There are a variety of ways that 3D printing benefits the manufacturing industry, such as:

- Outstanding medical or design advancements

- Decreased costs, including costs associated with labor and time

- More customization options

There are two prominent 3D printing methods that manufacturers can leverage to more efficiently produce goods:

- Fused Deposition Modeling

- Polyjet

Choosing the best method depends on what type of 3D structure you are designing and what material you are using, such as metal, plastic, concrete, ceramic, glass and cloth.

Each 3D printing method utilizes different materials and curing approaches; however, each method uses layering to form a three-dimensional structure.

One of the more recently developed 3D printing techniques is called cold spraying. It forms a metal structure by blasting metallic particles through a nozzle at such high speeds that particles bond together, molding into a shape. The user can control the nozzle until an exact 3D metal structure is formed.

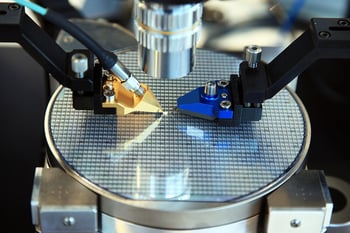

2. Nanomanufacturing

This is a hot manufacturing trend of the future! Today, nanomanufacturing is used mostly in space technology and biotechnology. However, future applications of this technology will give it an indispensable role in every manufacturing industry.

This form of manufacturing technology enhances the precision of many applications by altering materials on a supramolecular level. It’s medically transformative and offers a future possibility of microscopic robots that transport medicine through the body mending damaged organs and body tissue.

3. Flexible Electronics and Custom Apparel

Over the next couple of decades, advancements in flexible manufacturing are expected to transform the apparel and electronic industries. With bendable tablet computers and clothing items that acclimate to your body temperature, flexible electronics and custom temperature apparel will redefine shopping experiences and expand future manufacturing technology possibilities in the apparel industry.

4. Sustainable Manufacturing

The aim for sustainable manufacturing is to enable manufacturers to use minimal amounts of energy while maximizing production. Ideas for creating a more sustainable manufacturing environment include being able to produce goods in the “dark.”

The key to sustainable manufacturing is to build factories that are energy efficient;factories that do not need costly artificial light sources or machines that require extensive heating and cooling systems. Creating sustainable machinery and factories could be made more possible through intelligent robotic systems.

A Future of Innovation and Efficiency

Manufacturing has been rapidly transforming over the years. The industry is innovating ways for companies to be more resourceful and energy-efficient, while developing new methods of production.

Leave a Comment