December 30, 2020 | Lean

Lean Principles and Tools

Welcome to the second installment of our series on Lean and Six Sigma. As we saw in the first post, Lean and Six Sigma are complementary continuous improvement methodologies that reduce the overall waste and variability in production processes respectively. While these two methodologies use different approaches and tools to drive improvements in productivity and profitability, they have in common that they can be employed to improve every facet of your business.

Lean PhilosophyLean Pillars

Lean philosophy has two interconnected pillars: "Eliminate Waste" and "Respect for Humanity." These foundational elements greatly contribute to the success of Lean Manufacturing. Let's talk about them individually — the second one first.

The concept of Respect for Humanity manifests itself by respecting the workers and recognizing their inherent intelligence, creativity, and ingenuity. This is accomplished by empowering and challenging them to improve the products that they are making along with the production processes and tools employed to make them.

The concept of Eliminating Waste is the mechanism by which an organization increases its quality and profitability. From a Lean perspective, the customer sets the price based on the value they receive. Based on that customer-set price, the best way for a Lean organization to improve profitability and thrive is to eliminate any cause of low quality, delay in delivery, safety issues, and unnecessary cost — all defined in Lean as "waste."

5 Principles of Lean

- Understand "value" as defined by the customer

Understand in detail what the customer values and is willing to pay for in a given product, service or information - Define the value stream for each product

Identify all of the linked steps making up the current business and production processes that are required to transform inputs into the products, services and information that customers value - Establish continuous flow within the organization

Streamline processes, eliminating as much waste as possible so that quality products, services, and information flow smoothly through the value stream - Maintain flow throughout the use of a pull system

Based on continuous flow, align and balance production to meet demand "Just in Time" without excessive inventory, maintaining high quality and service levels - Pursue perfection through continuous improvement of the processes

Commit to relentlessly pursuing zero waste in all value stream processes by repeating these steps and adapting products, services and information to changing customer demands

"Non-Value Added" Work

As mentioned above, eliminating waste is a foundational pillar of Lean. To identify waste, all tasks currently being performed are viewed through the lens of value-added and non-value-added work. Value-added work directly creates the features, characteristics, and benefits that the customer desires and is willing to pay for (e.g., operating the machine that produces a plastic comb). Non-value-added work is made up of tasks that the customer does not care about and does not want to pay for (e.g., material and labor cost from scrap products passed on to the customer in the price of the comb). Some non-value-added work is necessary. For instance, tasks to meet a company's statutory reporting requirements are tasks that don't directly contribute to the production of the comb. While the customer buying the plastic comb may not really care about statutory reporting, the stockholders and employees of the company do — non-value-added but necessary. Either way, looking at all tasks being completed, streamlining, and ideally eliminating all of the unnecessary, non-value-added work is the goal. A number of studies have been conducted that show that in many organizations, upwards of 90 to 95% of the work done to produce a product or service is non-value-added work.

Lean Tools

There are a significant number of tools in the Lean toolkit — in excess of 20 or 30, depending on whom you talk to — all of which have application in various situations. Below is a list of a few of the foundational tools in Lean.

Policy Deployment (Hoshin Kanri)

Policy Deployment is a strategic planning and execution process. It is designed to ensure that overall company goals and strategies are defined and communicated up and down the levels of the organization. Further, through the process, all levels of the organization identify how their departmental and individual work goals map to the company goals and strategies. This alignment, down to the individual contributor level, ensures understanding and buy-in across the organization and eliminates waste by correcting misaligned goals before resources are expended.

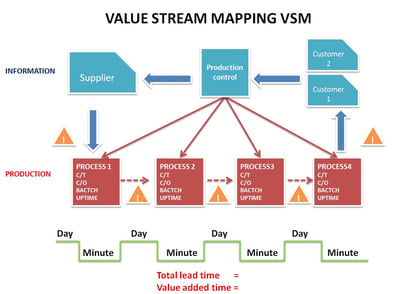

Value Stream Mapping

A Value Stream Map is a tool that allows for a ''horizontal'' view of the high-level steps involved in creating a product, service, or information. It documents all of the material and information flows in the process as well as the timeline across the value stream. It maps the current state of the process and brings visibility to opportunity areas on the path to the improved future state by contrasting total cycle time with value-added time.

The 8 Wastes

The 8 Wastes

In Lean, waste is typically identified as fitting into one of eight categories, all of which are non-value-added work. Just remember "D.O.W.N.T.I.M.E."

- Defects - Products, services, or information that do not match the customer's specifications

- Overproduction - Creating more product, service, or information than is demanded from the customer at a given time

- Waiting - Delays in the processing of product, and idle time experienced by people and machines due to unbalanced flow

- Non-Utilized Skills / Unused Creativity - Failure to match people to their talents, engage them, and empower them to develop improvements to the products and processes

- Transportation - The unnecessary movement of products or information

- Inventory (Excess) - Products, services or information over and above the amount being processed and that are not necessary to meet current customer demand

- Motion - Movement of people and/or machinery that does not add value to the product

- Excessive processing - Unnecessary, often outdated, process steps or activities that no longer add value to a product, service, or information

Root Cause Analysis - The 5 Why's?

In modern manufacturing facilities, there is a significant amount of complexity within the systems and processes used to create products, services, and information. When issues occur, the Lean approach is to not be content with dealing with the symptoms, but to work instead to identify the root cause. It is standard practice to ask and answer the question "Why?" at least five times to trace the causal chain back through the symptoms to the true root cause. This root cause is then resolved.

PDCA

In Lean, the process that is often used to achieve the elimination of waste is the PDCA cycle. It is an iterative process, sometimes requiring repeating several times before true root causes of waste can be identified and resolved.

PDCA is made up of the following steps.

-

Plan - Define the opportunity/goal and the changes required

-

Do - Make the changes to realize the opportunity identified

-

Check - Measure and evaluate the results of the changes made

-

Act - Standardize the new process or begin the cycle again based on results

5S / CANDO

5S comes from the Toyota Production System. It is about creating a work area that is set up for success where everything needed, and only that which is needed is where it is supposed to be to minimize waste in the process. Each S has a meaning based on the English near-equivalent of the Japanese words. They are:

Sort - Sort all materials in the work area and remove anything that is not needed

Set in Order - Organize the needed items and establish a place for everything

Shine - Frequently clean the work area

Standardize - Establish documented standards for the Sort, Set in Order and Shine steps

Sustain - Inspect and reinforce the standards set

5S is an adaptation of a similar process created by Henry Ford in the 1920s called CANDO:

Cleaning up, Arranging, Neatness, Discipline, Ongoing improvement

Rapid Changeovers (Single Minute Exchange of Die - SMED)

Have you ever watched a NASCAR race and wondered how they change four tires and fill a tank of gas in 7.3 seconds? It's through the application of Rapid Changeovers or S.M.E.D. techniques. Rapid Changeover processes reduce set-up and transition times for machines and processes. In Lean, the goal of reduced set-up and changeover times is to increase production scheduling flexibility by reducing optimal batch sizes. Rapid Changeovers are achieved through a five-step methodology:

Step 1 - Observe and study the set-up of changeover process steps/activities

Step 2 - Classify the steps/activities as internal and external. Internal steps can only happen when the machine/process is stopped - e.g., the car is in the pits. External steps can happen while the machine/process is running - e.g., the car is out on the track.

Step 3 - Convert internal process steps/activities to external

Step 4 - Look for ways to reduce the time and effort required for the remaining internal steps

Step 5 - Look for ways to reduce the time and effort required for the remaining external steps

Kanban

A Kanban is a methodology to structure the flow of materials through a manufacturing process that is based on pull. It is typically based on Kanbans, or pull cards, that signal upstream processes which parts to produce and in what quantities based on downstream needs. A Kanban system minimizes inventory levels and overproduction waste.

Kaizen

Kaizen is a Japanese term that can be translated as "Change for the Good." It is the process of continuously making incremental, often daily, improvements in processes by enlisting the perspectives of line-level employees to harness their creativity and ingenuity. Kaizen can be done live on the production floor as opportunities are identified or in conference room events for cross-functional opportunities. A Kaizen team will often employ the PDCA cycle.

Error Proofing (Poka-Yoke)

One way to eliminate waste is to design processes and tools in a way that makes it impossible to complete the task incorrectly. Think of a standard U.S. three-pronged electrical plug. Due to the two parallel rectangular features and the single round one offset between, it is not possible to plug it into a receptacle incorrectly. It only fits one way. By ensuring that tasks cannot be done incorrectly, quality is built in, and waste is eliminated at the given workstation, as well as at any workstation later in the process where the defect impact would be magnified.

Standard Work

In lean, the steps to accomplish a given task of activity are codified into standard work. Standard Work is essentially documentation of the currently best-known method to accomplish a task. "Best known" because, in a continuous improvement system, workers are always on alert for even better ways to do their jobs. Any improvements are incorporated into the standard work documentation, and all workers are then trained on the latest methods.

For more information on Lean and Six Sigma, check out our third installment in the series, “Six Sigma Principles and Tools,” coming soon.

Who We Are At CMTC

CMTC offers technical assistance, workforce development, and consulting services to small and medium-sized manufacturers (SMMs) across California to help SMMs increase their productivity and global competitiveness.

For more information about CMTC, visit our website at www.cmtc.com or contact us at 310-263- 3060.

About the Author

Gregg Profozich

Gregg Profozich is a manufacturing, operations and technology executive who believes that manufacturing is the key creator of wealth in the economy and that a strong manufacturing sector is critical to our nation’s prosperity and security now, and for future generations. Across his 20-year plus career in manufacturing, operations and technology consulting, Mr. Profozich helped manufacturing companies from the Fortune 500 to the small, independents significantly improve their productivity and competitiveness.

Leave a Comment