Electronic Precision Specialties has been providing quality electroplating services for the Electronic, Telecommunications, Medical, and Aerospace industries since 1980. In 1985, the current ownership led by Henry "Hank" Brown, has dedicated itself to providing quality first electroplated finishes for our Customers. Our commitment to quality includes invest in new equipment and technology which has enabled us to offer customers unequalled quality, service, and reliability while maintaining our responsibility to the environment and community in which we work.

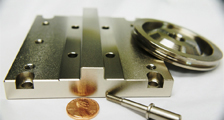

EPSI is a precision plating facility, located in Brea, CA. dedicated to the stringent requirements necessary for our customers' industries. EPSI's team is very adept at evaluating and resolving difficult plating related issues, while providing new alternatives for old problems. Parts with deep ID's, complex shapes, and dimensional considerations are the specialty of EPSI's daily production.

The processing systems utilized by EPSI include:

MRP/SIBS program - use of barcodes to identify all received product with tracking ability throughout the processing of product. Information accessible including planning, processing and results to all E.P.S.I. associates via SIBS program.

TruChem - a chemical laboratory control program monitoring the results of real time daily analysis, providing SPC and analysis of the chemistries necessary for quality plating.

SimpleTrak - program for monitoring calibrations of equipment as well as continuous improvement projects, reject determinations, corrective actions and Management review of the Quality Management System governed by our ISO 9001/2008 Certification.

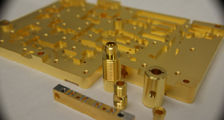

We specialize in rack, barrel, and vibratory plating of metal stampings, screw machined, EDM, and CNC machined parts. We provide electroplating of Gold, Silver, Nickel, Rhodium, Tin-Lead, Copper, and Palladium-Nickel per our customer's requirements.

Rack, Barrel & Vibratory Plating Services

Gold Plating: Low contact ressistane, excellent bondability and solderability

Silver Plating: Ellecent lubricity, high electrical and thermal conductivity

Nickel Plating: Corrosion resistance, good barrier plate and wear resistance

Tin-Lead Plating: Improved solderability over long periods, prevent whisker growth

Rhodium Plating: White bright finish for excellent wear and corrosion protection

Copper Plating: Provides good foundation for corrosion resistance and solderability

Palladium-Nickel Plating: Corrosion resistance, low porosity, low contact resistance

Company Name: Electronic Precision Specialties, Inc.

Category: Metal Coating & Electroplating

Location: Brea, CA

Contact Person: Gary Hein, VP Sales/Marketing

Phone: Work: (714) 256-8950 Mobile: (714) 519-9423

Email: @

Website: www.elecprec.com

To meet the most stringent manufacturing requirements in the industry, Henry “Hank” Brown knew that the manuals and procedures in his electroplating facility had to be more automated. The president of Electronic Precision Specialties also knew that a certification from the National Aerospace and Defense Contractors Accreditation Program equaled happy customers. So he hunted for the best technology and accomplished his goal fast.

| Phone: | (310) 263-3060 |

|---|---|

| Contact CMTC: | Contact CMTC Here |

| Address: |

California Manufacturing Technology Consulting® (CMTC) |