April 12, 2017 | Additive Manufacturing

5 Major Benefits of Additive Manufacturing You Should Consider

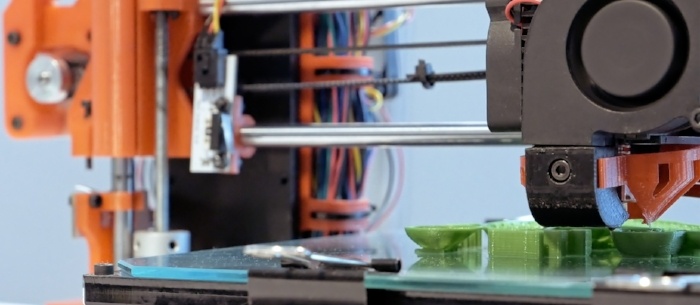

Since the introduction of 3D printing in the 1980s, the benefits of producing small amounts of complex parts have been well understood to manufacturers. With new technology coming out and so many companies turning toward additive manufacturing in recent years, more and more advantages are being revealed on a regular basis.

Still, some companies remain on the fence about additive manufacturing and aren’t convinced it is the future. For these companies, we would like to discuss five major additive manufacturing advantages to consider:

1. Cost of Entry is Becoming More Affordable

The first obstacle most companies face when contemplating additive manufacturing is the cost of equipment. Machinery for additive manufacturing has historically been too expensive for smaller manufacturers to accommodate. However, new technologies have made the cost of entry much more affordable, cutting equipment costs as low as $3,500.00 for a reliable industrial quality machine.

Because additive manufacturing has the capability to reduce the amount of capital that is needed to scale up production without making major changes, manufacturers may be able to increase the speed and profitability of their business model.

2. It Is Easy to Change or Revise Versions of a Product

Additive manufacturing is about more than just creating a physical product, it is about bringing design and innovation to the forefront. In fact, having creative freedom without worrying about cost or time penalties is one of the primary advantages of additive manufacturing.

In traditional manufacturing, modifying a design during production can lead to significant cost increases or time delays as tooling on a production line is changed out. Additive manufacturing solves this problem by moving away from static designs and enabling engineers to produce multiple versions of a single design in a cost-effective manner.

3. Training Programs Are Becoming Readily Available at All Levels

You might think that training your staff to design for additive manufacturing will be a challenge that will interrupt business operations. This is not necessarily the case as there are a wide variety of training programs available for designers and manufacturers at all levels of understanding.

For example, fundamental training is available for those who have experience with the tools or technology; technical training is available to educate decision makers on how to utilize additive manufacturing; and advanced training is available for education on material handling and post-production processes.

4. It Reduces Waste Production

Additive manufacturing generates significantly less waste than traditional manufacturing methods. For example, a milling machine works by removing material from a block that is bigger than the product itself will be. The removed material is usually in the form of kindling or shavings that cannot be reused and therefore end up as waste.

Additive manufacturing, on the other hand, works differently. Instead of removing material, it “adds” material layer by layer so that only what is required gets used. In this way, additive manufacturing can reduce material costs and waste by as much as 90 percent.

Compared to traditional manufacturing processes, AM can significantly reduce energy usage5. It Saves on Energy Costs

When compared with traditional manufacturing processes, additive manufacturing can significantly reduce energy usage by using less material and eliminating steps in the production process. Take this example cited in a recent report by the Department of Energy:

“LEAP jet engine from GE and Snecma incorporates fuel nozzles printed with laser sintering. Conventional manufacturing process welds 20 parts to produce the fuel nozzle, while AM produces a single piece that is 25% lighter, five times more durable, and reduces fuel burn by 15%”

Furthermore, re-manufacturing parts through additive manufacturing processes can return end-of-life products to “like new” condition using only 2 to 25 percent of the energy that would be required to build a whole new part.

Demand Continues to Rise

As the need to obtain parts quickly continues to rise, additive manufacturing processes will continue to become more and more relevant in the future. AM equipment manufacturers are predicting that as more companies begin to adopt these technologies, it is only a matter of time before the future of manufacturing is completely transformed.