KAP Manufacturing was formed in 1997 with the goal of providing customers in the Aerospace and Defense Industry with quality parts from a precision machine shop. Customer satisfaction is the measure of success at KAP, and is achieved through a focus on the integrity, input and capabilities of its employees. KAP Manufacturing employs 22 people in its San Dimas office, and manufactures precision parts in Aluminum, Titanium, Stainless Steel, and Inconel.

Challenge

As part of KAP’s strategic plan to focus on the Aerospace and Defense Industry, KAP obtained AS9100 certification of their Quality Management System. AS9100 is a widely recognized quality management system in the aerospace industry requiring an accredited third-party audit to achieve certification. With an impending certification audit, KAP wanted a quick training and upgrade program of their current QMS to the Rev. D standard. Management was additionally concerned about how the new rigorous revision D guidelines included in the certification process could be implemented in the short time frame available.Solution

In August 2017, KAP Manufacturing connected with CMTC. After a kick-off meeting and system evaluation, consultants worked with the organization to develop an implementation plan to become AS9100 revision D certified by November 2017. CMTC assisted KAP Manufacturing in identifying and implementing the required operational improvements. This required editing and augmenting the internal management system and documentation with the necessary procedures and processes. CMTC provided the organization with templates and training guidelines to help management more efficiently implement the changes associated with the new AS9100 Rev. D standard.

To address any concerns about the timing of the project, CMTC worked closely with the staff on an intensely scheduled project. Staff members were trained on the changes to the AS9100 standard and were actively encouraged to provide feedback during the process. Consultants were able to balance the tight schedule of training and implantation to complete the project on schedule. After training was conducted, CMTC led KAP Manufacturing through internal audit training. The company was guided through a simulated audit and addressed possible areas for improvement.

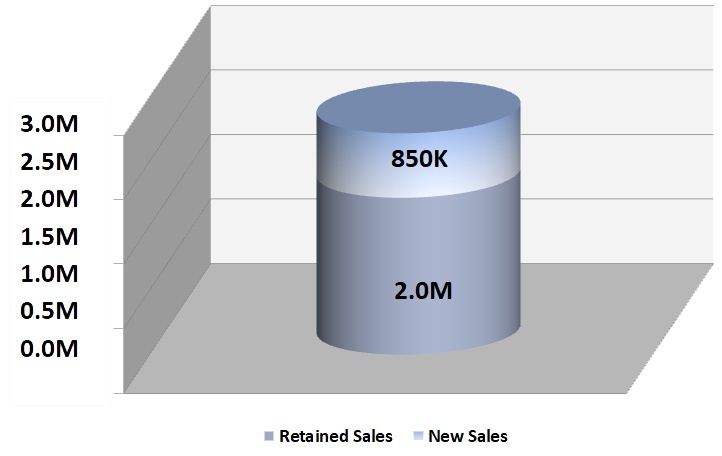

Training and consulting concluded in November 2017 and KAP Manufacturing successfully passed the audit to achieve AS9100 Rev. D certification. As a result, the organization was able to continue to meet the requirements of their larger aerospace clients and retained $2,000,000 in sales. Certification will also allow KAP Manufacturing to continue to compete for new business from aerospace and defense industry clients. The organization projects it will achieve $850,000 in increased sales from new clients.

“CMTC was very professional and extremely responsive to our needs with highly skilled consultants and trainers. The interaction and correlation between CMTC and KAP was seamless.”

- Kathy D’Amato, President

Download This Case Study

$2,850M Total Sales

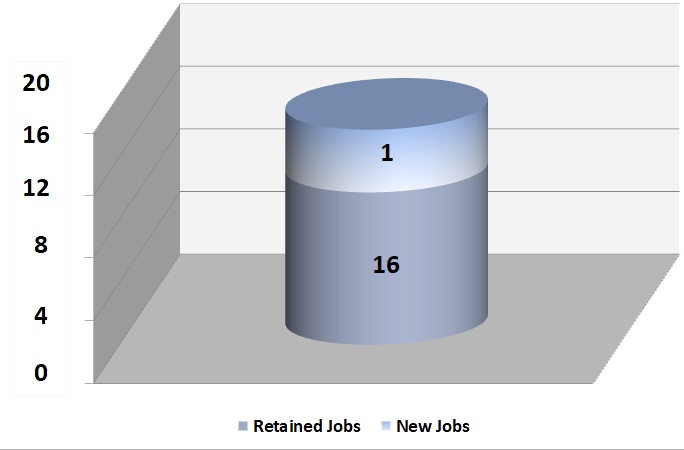

17 Jobs Created & Retained

Financial & Productivity Results

- $850K in new sales sales

- $2M in retained sales

- 1 jobs created

- 16 jobs retained

- $15K in cost savings

Case Studies

- Additive Manufacturing (3)

- Aerospace and Defense (14)

- Apparel (3)

- Business Growth Strategy & Strategic Planning (28)

- Continuous Improvement (8)

- Employee Training (14)

- Energy (7)

- Exporting (4)

- Farming (1)

- Food and Beverage (16)

- Fourth Industrial Revolution (24)

- Health & Safety Services (3)

- Industrial (1)

- Information Technology (3)

- Innovation & Growth (17)

- Lean (35)

- Machinery (1)

- Made in California (7)

- Manufacturing Technology (3)

- Medical (1)

- Plastics and Rubber (1)

- Quality (27)

- Sales and Marketing (32)

- Smart Manufacturing (1)

- Supply Chain Management (1)

- Wood (1)