Medical

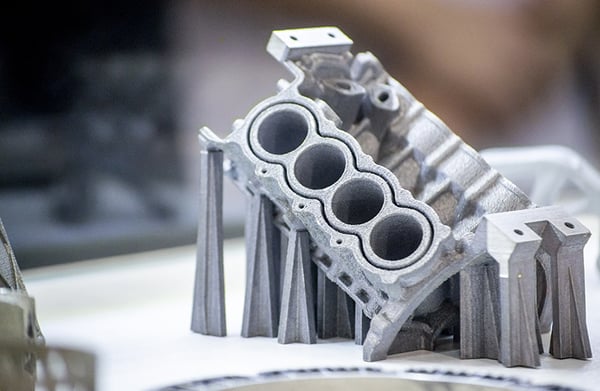

Additive manufacturing has revolutionized the medical industry, delivering breakthroughs to doctors and patients alike.

Dentistry: Currently, the 3D printing market for digital dentistry is valued at $2.5 billion — and that’s expected to grow. Additive manufacturing allows for 3D printed dental appliances and custom-made devices, such as dentures, crowns, and even Invisalign™, to be constructed from a variety of substrates and prints customized to each individual.

Anatomical Models: True-to-life anatomical models can be printed with relative ease due to 3D printing, which is helpful for students, researchers, and in surgical preparation.

Prosthetics & Devices: Additive manufacturing allows for the creation of durable prosthetics that can be customized to assist the recipient’s bone structure and their unique needs while being strong, lightweight, and still pliable for comfort. Likewise, devices such as hearing aids can be mass-produced using additive manufacturing and made for a better fit to ensure the highest level of comfort for the user.