The global number of IoT-connected devices is expected to reach 43 billion by 2023.

Some Key Statistics About the IIOT

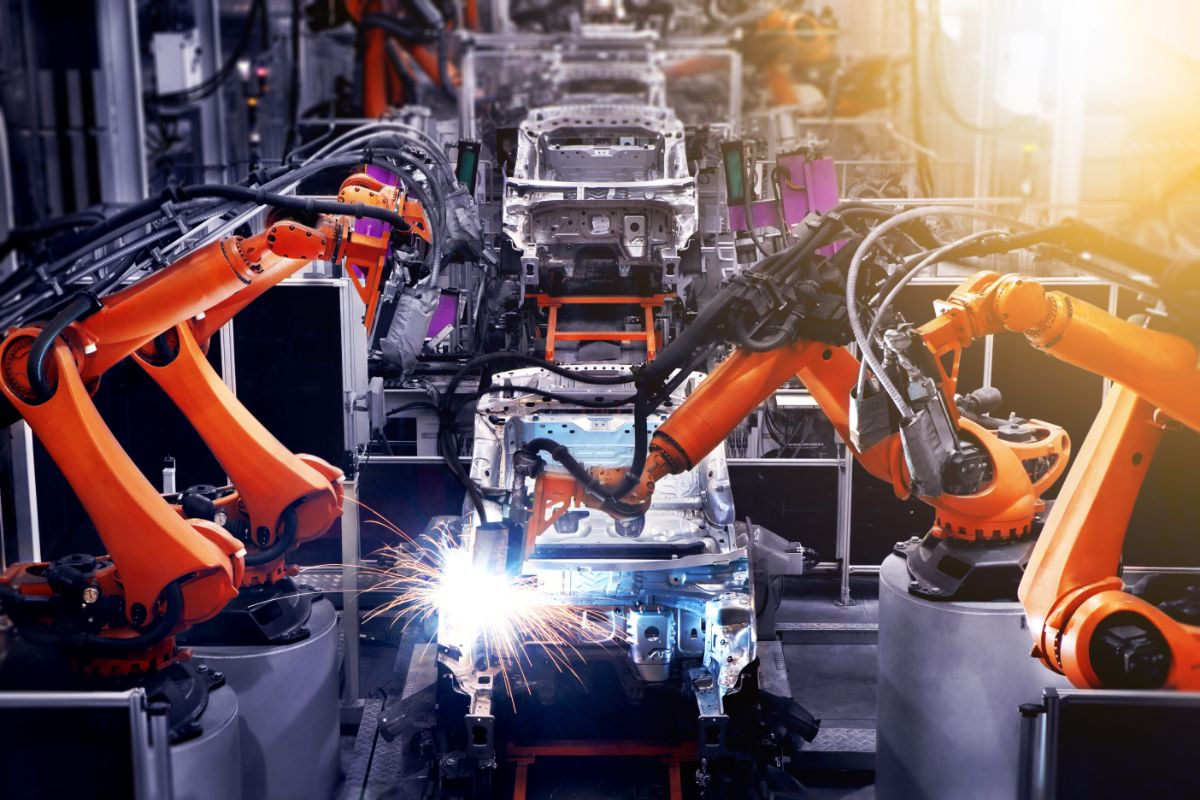

Smart manufacturing technology allows manufacturers to automatically collect and analyze data from a variety of sensors and machines. This data is then communicated to the cloud by IoT connectivity solutions deployed at the factory level.

In fiercely competitive global markets, these powerful data insights allow you to make

better-informed decisions and optimize production!