Malama Composites, Inc. is the leading innovator of non-toxic rigid foams made with bio-based or recycled PET (plastic bottles). We have successfully commercialized the world's first full line of cost competitive, sustainable rigid foams. Two of the products in Malama's product line have earned USDA bio-based certification and federal preferred purchasing status. Malama's solutions compete cost effectively with PIR, PUR and phenolic foams.

Studio BioFoamĺ¨ Sculpting Foam ŰŇ Artistry Without Toxicity

Studio BioFoamĺ¨ is an ideal carving medium for artists, designers, students and hobbyists and is a USDA Certified Bio-based Product and identified for Federal Preferred Purchasing. Studio BioFoamĺ¨'s light weight, dimensional stability, shaping characteristics, and compatibility with water and solvent based paints, coatings and adhesives make it an ideal sculpting medium for theatre scenery, trade show exhibits, museum installations, TV shows, retail environments, orthotics, prosthetics, theme parks, and 3D signage. Trade show exhibits are particularly well suited to the product because of the need for rapid production and weight reduction.

Pacific BioFoam 2 Part Foam ŰŇThe First Bio-based Two Part Pour Foam to Deliver Competitive Pricing and Performance

Pacific BioFoam㢠is the first two-pound density, castor based, pour foam that is a non-toxic material. The product has the highest bio-content of any commercially available rigid urethane foam on the market and uses water as its sole blowing agent. Pacific BioFoam㢠is ideal for a wide range of industrial applications including insulated packaging, consumer appliances, and automotive applications, moldings, casting and formwork.

AinaCoreĺ¨ ŰŇ Higher Moisture Resistance and Lower Cost Than Phenolic Foams ŰŇ Competitive Fire and Insulation Performance

AinaCore SI 2.0 is a two-pound closed cell polyisocyanurate (PIR) foam with the highest fire rating and insulation value in its class.

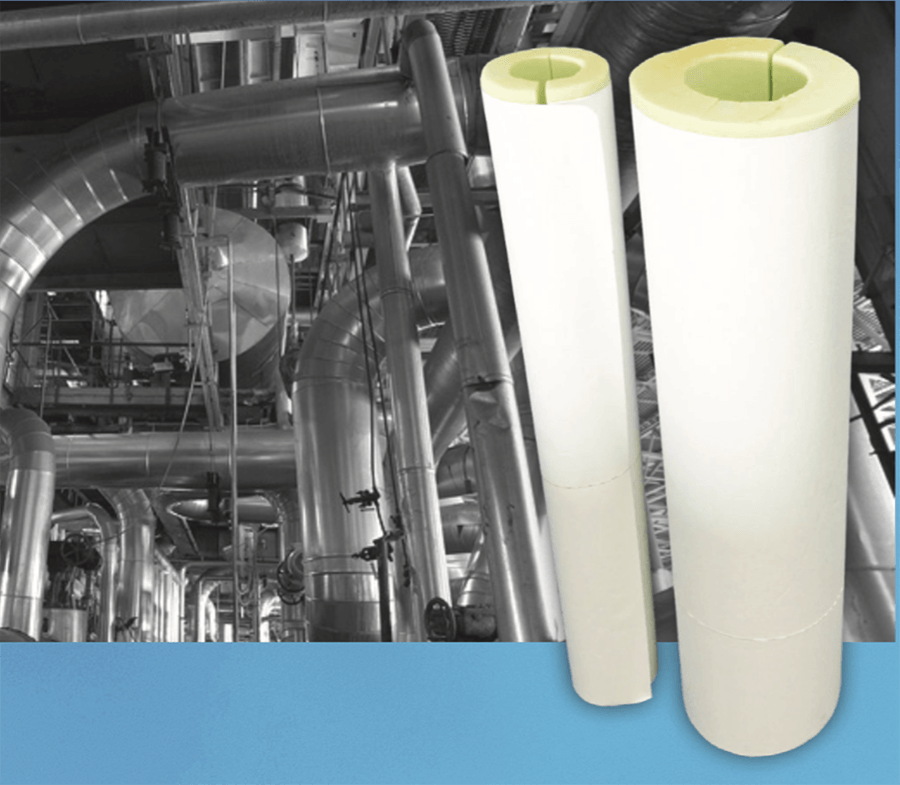

Innovation in Pipe Insulation Insulation Starts Here

Bay Insulation and Malama Composites have teamed to deliver commercial pipe insulation with superior technical and environmental performance at a lower price point than phenolic alternatives.

Malama's foams utilize methylene diphenyl diisocyanates (MDI) for the A-side, and polyols derived from plant-based renewable resources such as castor or recycled PET (plastic bottles) for the B-side. Pacific BioFoam is shipped to customers as a 2-part pour foam.

In the manufacturing process for our rigid foams ŰŇ Studio BioFoam and AinaCore ŰŇ A-side and B-side chemicals are placed in separate pressurized tanks. The A-Side and B-Side chemicals come together in a mixing chamber and are immediately dispersed across a 54Ű wide moving belt. The formula rapidly expands to over 30 times its original volume, rising up the sides of the line while solidifying. Moving at a rate of about 10 feet per minute, the horizontal column of foam hardens sufficiently enough to be cut in eight-foot lengths, removed from the line, and stacked for curing.

After seven days, raw buns are loaded into trucks and shipped to Malama's post-production facility to be trimmed and dimensioned on a large panel to create billets of final product. For customers requiring specific panel thicknesses, dimensioned buns pass through a second band saw that slices them to exact tolerance. Finished goods are palletized and labeled for shipment to our distributors or customers.

Company Name: Malama Composites,Inc.

Category: Plastics & Rubber Products

Location: San Diego

Contact Person: David Saltman

Phone: 858-560-0760

Email: @

Website: http://www.malamacomposites.com

Recent Media Coverage:

September 9 - BioPlastics Magazine - Malama Composites Earns USDA Bio-based Product Certification and Label for Pacific BioFoam

September 3 - Bio-Based News - Malama Composites Earns USDA Bio-based Product Certification and Label for Studio BioFoam

September 2 - JEC Composites - Malama Composites Earns USDA Bio-Based Product Certification

September 1 - Xconomy - Malama Composites Gets USDA's "Biobased" Product Certification by Bruce Bigalow

May Issue - Business in Focus Magazine - Making our Homes as Smart as Our Phones - by Leon Bracey - Business in Focus profiles Malama Composites

April 13 - Advanced Manufacturing Insight - Bio-Based Materials Growing into the Building Blocks of the Future - by Ryan Brinks

April 10 - Prospector - NPE Design Panel: Storytelling and Emotion Can Help Drive Sustainability - by Robert Grace

March 30 - Plastics News - Panel Seeks to Bridge the Gap Between Designers,Engineers - by Hamish Champ

Recent Media Releases:

August 27 - Press Release - Malama Composites Earns USDA Certified Biobased Product Certification and Federal Preferred Purchasing for Pacific BioFoamă˘

August 26 - Press Release - Malama Composites Earns USDA Certified Biobased Product Certification and Label for Studio BioFoamĺ¨

Product Flyers:

Studio BioFoam - Shape Your World with Zero Toxicity

Innovation in Pipe Insulation - 25/50 We've Got You Covered

AinaCore Structural Insulation ŰŇ Higher Moisture Resistance and Lower Cost Than Phenolic Foams

Roof Tiles incorporating AinaCore by Eternatile

Pediment sculpted of Studio BioFoam by the San Diego Natural History Museum