February 25, 2014 | Supply Chain Management

Supply Chain Optimization vs. Supplier Development: Key Differences

|

Written by: Terry Weiner The following post is #9 of a series and discusses Supply Chain Optimization vs. Supplier Development. This series of posts provides an overview of the Supply Chain Optimization process and previews some of the concepts and tools that are part of the Manufacturing Extension Partnership (MEP) Supply Chain Optimization Initiative. Click here to read earlier posts. |

How Can You Determine Supply Chain Optimization vs. Supplier Development?

How Can You Determine Supply Chain Optimization vs. Supplier Development?

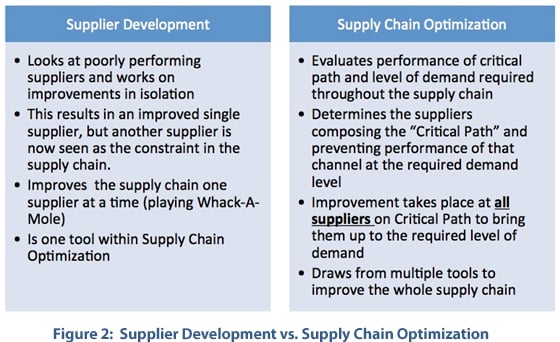

When we experience disruptions in the supply chain whether it is caused by late deliveries, long lead times or poor quality, we look for the link in our supply chain that is causing the problem. Typically, we then try to work with that supplier to help them to improve whatever is creating the problem. Failing an adequate improvement, we look for a new supplier. This is “Supplier Development.”

When we experience disruptions in the supply chain whether it is caused by late deliveries, long lead times or poor quality, we look for the link in our supply chain that is causing the problem. Typically, we then try to work with that supplier to help them to improve whatever is creating the problem. Failing an adequate improvement, we look for a new supplier. This is “Supplier Development.”

Supplier Development has been the traditional method used to improve supply chain performance. The suppliers causing the most problems in cost, delivery or quality are the recipients of our improvement efforts. The idea being that if I can just get this supplier to perform, all my supply chain problems will be solved.

More often than not, once the supplier we help is brought up to the desired performance level, we discover that the flow of product hangs up at yet another node in the supply channel. We then proceed through the supply chain in “Whack-A Mole” fashion “improving” each new supplier that emerges as “the problem.”

We might also find that some suppliers just don’t have the capacity to provide product at the level of demand required or they may not have the ability to respond quickly to changes in demand.

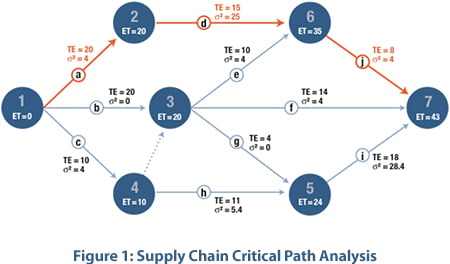

In the 4th article in this series, “How to Create a Road Map to Supply Chain Optimization”, we discussed mapping the supply chain and performing a critical path analysis to identify the supply chain constraints and the suppliers who lie on the critical path.

Critical Path Analysis helps us to determine the rate of demand required of each channel of our supply chain in order to meet our top tier strategy. The strategy we created earlier includes projected demand for near term, and long term. We can then look at the channel that composes the critical path and create an improvement plan that will bring the entire channel’s ability to a level that can meet the demand.

The forecasted demand levels are shared with each of our supply chain partners and their capability to meet the capacity, quality and lead time requirements are assessed.

An improvement plan is developed with each partner to assist in bringing their performance in these areas to the levels required. When this has been achieved, we have optimized the supply chain.

For a quick overview of the CMTC Supply Chain Optimization Roadmap that has been developed in conjunction with the Manufacturing Extension Partnership Program (MEP), you can download the Supply Chain Roadmap.

What's Next?

In future posts, we will look at the following components of the Supply Chain Optimization Initiative - Link by Link:

Terry Weiner is a Senior Consultant with California Manufacturing Technology Consulting® (CMTC). He has over 20 years experience in process improvements, quality management implementation and supply chain optimization.