September 24, 2019 | Made in California

What Are Makerspaces and How Do They Benefit Manufacturers?

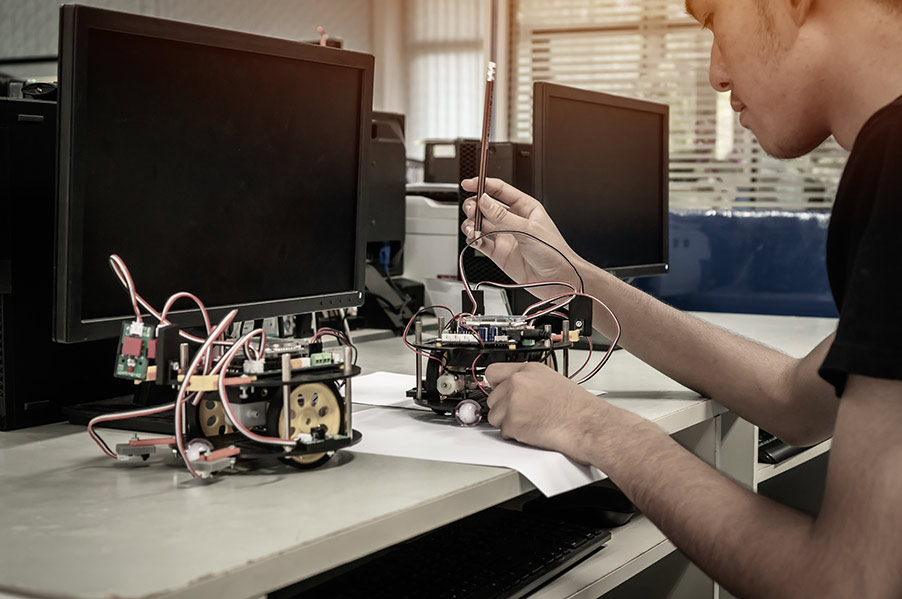

If you remember the woodworking, metalworking, and auto shop classes that used to be taught in high school, you already have an idea of what a makerspace is. Makerspaces, sometimes called Maker Labs, are defined as “a place in which people with shared interests can gather to work on projects while sharing ideas, equipment, and knowledge.” Of course, today, there is usually a lot more technology involved, as makerspaces put more focus on STEM (science, technology, engineering, and mathematics) concepts.

Makerspaces can be found in classrooms, corporate facilities and manufacturing plants, and as standalone operations. Much like Manufacturing Day, makerspaces are inspiring the next generation of workers, fostering entrepreneurship, and giving employees at all levels the opportunity to innovate.History of the Makerspace Movement

Makerspaces as we know them today got their start in Germany the 1990s, when they were known as “hackerspaces.” These were open community labs incorporating elements of machine shops, workshops, and/or studios where hackers could get together to share resources and knowledge to build and create things. While hacking today now conjures up negative images of cybercriminals out to bilk companies out of millions, the term hackerspace simply meant that the individuals in the group would attempt to “hack” technology or objects to make them do something they weren’t intended for in order to further innovation.

It wasn’t long before the concept moved outside of Germany’s borders, with the name evolving to “makerspace” to avoid those negative connotations. The most recent numbers reported by Popular Science in 2016 revealed that there were nearly 1,400 active standalone makerspaces across the globe, 14 times more than the decade prior (surely, this number has only increased in the years since). In the United States, California, New York, and Texas lead the way in standalone makerspace development, representing 25% of the total U.S. makerspace market.

Three Types of Makerspaces

Makerspaces can be found in classrooms, corporate facilities and manufacturing plants, and as standalone operations. Here’s a look at each, and the benefits they offer users.

Classrooms and Colleges

Makerspaces in schools run the gamut from designated rooms that students rotate between, to mobile carts moved from classroom to classroom. They aren’t limited to certain materials, either. For some subjects, the makerspace may include items like cardboard and duct tape; for others, it may include laptops, microphones, and green screens.

It’s all about giving students a hands-on experience that gets them thinking outside the textbook box. “We know that students learn at a deeper level and they retain more when they’re engaged in creative thinking connected to the subject, right?” says John Spencer, co-author of the book Launch: Using Design Thinking to Boost Creativity and Bring Out the Maker in Every Student. “So to begin with, just within the content area, (making is) going to allow for deeper learning... in a makerspace, you’re actually going to create some kind of product. It could be a physical product...a digital product...but there is an actual product.”

Corporate and Manufacturing Facilities

Makerspaces have begun popping up in corporate and manufacturing facilities, and Mark Hatch, an advocate for the builders, doers, and tinkerers known as the “maker movement,” is at the forefront of what he calls a revolution. For Hatch and others like him, makerspaces in the workplace are an opportunity to reshape the approach to intellectual property development. To create a makerspace, Hatch told the Association of Equipment Manufacturers (AEM) that companies just need to open a workshop with a variety of tools, which can include a 3D printer, a laser lab, woodworking equipment, CNC routers, metal fabricating equipment, welding gear, plastic fabricators, and textile producers. “A million dollars in tools, and you can have a makerspace that can create hundreds of millions of dollars in income or savings for your company,” says Hatch.

He points to Ford’s initial launch of a makerspace at its facility in Dearborn, Michigan. Within the first year, he says the company registered a 200% increase in intellectual property development. Some of those innovations, which have already been incorporated into finished protects, were developed by non-traditional employees who were empowered to develop ideas in a makerspace and pitch them to executives.

Standalone Operations

Of course, not all corporations and many small and medium-sized manufacturers (SMMs) can’t plunk down one million dollars to create their own fully-equipped makerspace. Just to get their hands on a decent 3D printer can still cost between $600-$6,000. As a result, standalone makerspace operations (also known as “fab labs”) have been popping up around the country. These creative outlets generally have a very inexpensive monthly membership, allowing workers from any size business or SMM to sign up and participate.

They also often offer classes and workshops to introduce people to the equipment they may not be familiar with in order to get them up and running. Being community-based, standalone makerspaces allow people to interact with others inside and outside of their field; don’t be surprised to run into budding entrepreneurs and owners of startups working away inside.

Embracing the Manufacturer Makerspace

Many companies and manufacturers rely on those in executive positions to determine what’s next; however, it could be the person on the line or toiling away in the marketing or IT department who has a superior solution. With a makerspace, anyone can create the next big thing, or put to rest ideas that just won’t work. Makerspaces allow anyone—students, workers, and executives—to turn ideas into products. They inspire, encourage, and lead to innovation whether they’re in-house or off-site. After all, you never know where the next great idea may come from.

Another way to encourage the next generation and inspire new potential leaders? Participate in Manufacturing Day. Manufacturers across the country are preparing for Manufacturing Day® 2019, or MFG Day. Arriving October 4 this year and continuing throughout the month, MFG Day is designed to inspire and recruit the next generation of manufacturers by providing a look behind the curtain and offering hands-on experiences, much like today’s makerspaces. Want to get involved? Click below to learn more.