February 6, 2014 | Supply Chain Management

What are the “Twin Killers of an Efficient Supply Chain?

|

Written by: Terry Weiner The following post is #8 of a series and discusses the twin killers of an efficient supply chain. This series of posts provides an overview of the Supply Chain Optimization process and previews some of the concepts and tools that are part of the Manufacturing Extension Partnership (MEP) Supply Chain Optimization Initiative. Click here to read earlier posts. |

The Twin Killers of an Efficient Supply Chain

The “Twin Killers” – Dependency and Variation

The efficient flow of material through Supply Chains is subject to slow downs and interruption by what are known as the “Twin Killers” of flow – Dependency and Variation.

Dependency is defined as:

- Existence of unavoidably dependent events

- Interactions between resources and products (capacity & supply with demand)

- Bottlenecks and a Constraint

Variation is defined as:

- Statistical variation

- Random events

- Batch processing

- Planning assumptions

- The bullwhip effect

Understanding what these dependencies are and where/when they occur is important in optimizing supply chain costs and TCO. Not recognizing them makes an organization vulnerable to unpleasant surprises, which can drive up costs.

A Supply Chain or Value System map can help identify these dependencies. We need to look at a supply chain as a system.

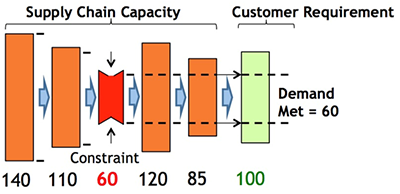

Each system is limited by a constraint, which prevents it from achieving a higher performance relative to its goal.

In order to manage the performance of the system, the constraint must be identified and treated carefully.

Bottleneck vs. Constraint

A bottleneck limits locally the flow (e.g. to small waiting room, fluctuations): 1hour lost might be 1hour (or less) lost for the whole.

The constraint is a bottleneck that limits the whole chain: 1hour lost is definitely 1hour lost for the whole:

AGAIN: bottleneck (local) vs. constraint (whole)

Local limitation (bottleneck) can be recovered locally, thus it does not automatically affect the constraint (whole); depends on the local ‘recovery capabilities’ Constraint always has impact on the whole.

Optimizing the Supply Chain

Supply chain optimization depends on having a supply chain strategy that clearly defines the projected demand over time and then improving the identified critical path in the supply chain so that all suppliers are capable of meeting that demand (removing the constraints) and that there is sufficient capacity within the critical path to adjust to fluctuations in demand (variation). This needs to be accomplished along the entire critical path or the constraint will simply move from one node in the chain to another.

What's Next?

In future posts, we will look at the following components of the Supply Chain Optimization Initiative - Link by Link:

|

How Can You Determine Supply Chain Optimization vs. Supplier Development? |

|

The Final Link - Creating Supply Chain Visibility |

|

How do I Assess Supply Chain Maturity? | ||

Terry Weiner is a Senior Consultant with California Manufacturing Technology Consulting® (CMTC). He has over 20 years experience in process improvements, quality management implementation and supply chain optimization.