Challenge

In 2012, ANP wanted to increase sales by expanding its product line. ANP wanted to embrace the recent advancements in the field of LED lighting to develop new products and support growth. Adapting to the new technologies and manufacturing methods required an investment in new equipment and processes which ANP would need to enter the LED market. The company needed to reduce production costs by becoming more efficient and Lean and invest those savings into new LED product development.

Solution

ANP Lighting met with CMTC in May, 2012. CMTC consultants started a Lean Improvement Project which included Lean training that was designed to help ANP work more effectively and improve their processes. The project involved a careful analysis of the facility’s layout and a reorganization of the production floor to increase efficiencies. Unneeded materials were removed from the workplace and equipment was relocated to increase convenience for employees. The team also revamped its processes to accommodate the new layout.The project concluded in June, 2012. The time and money saved by the project permitted ANP to invest resources into the equipment, processes and workforce developments required to expand its product line. The investments allowed the company to innovate new LED lighting products, create new lighting lenses and lanterns, which resulted in $700,000 in new sales. The organization expects to continue growing.“As a small company taking steps to grow, CMTC was an incredible resource. Their team helped us improve our production processes and guided us to become more efficient, lean and organized. CMTC’s training allowed us to reduce production costs and invest resources in new product developments. The result was increased sales.”

--Bob Foster

Production ManagerDownload This Case Study

$1M in Total Sales

(Dollars in Thousands)

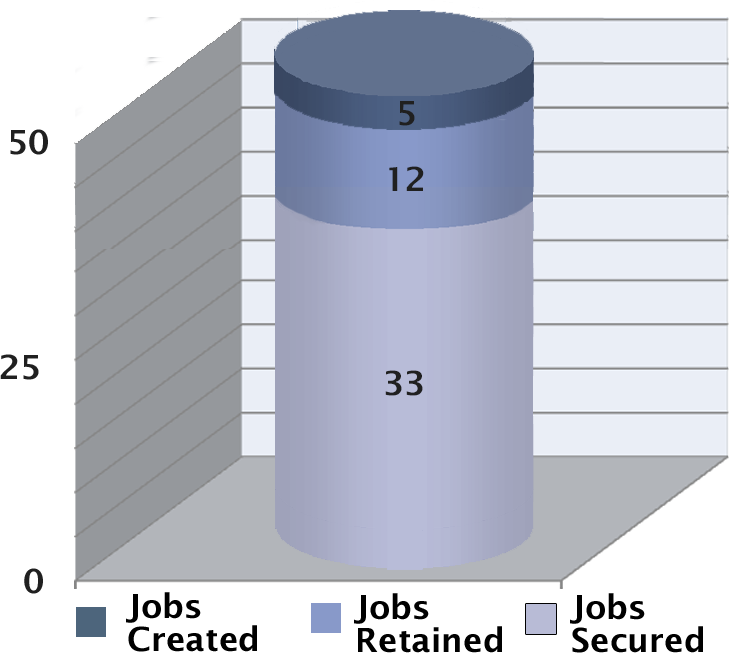

17 Jobs Created and Retained

Financial & Productivity Results

- $700,000 in new sales

- $300,000 in retained sales

- 5 new jobs created

- 12 jobs retained

- $120,000 in costs saved

- $23,000 in plant, equipment and new product investments

- $12,000 in workforce development investments

Case Studies

- Additive Manufacturing (3)

- Aerospace and Defense (14)

- Apparel (3)

- Business Growth Strategy & Strategic Planning (28)

- Continuous Improvement (8)

- Employee Training (14)

- Energy (7)

- Exporting (4)

- Farming (1)

- Food and Beverage (16)

- Fourth Industrial Revolution (24)

- Health & Safety Services (3)

- Industrial (1)

- Information Technology (3)

- Innovation & Growth (17)

- Lean (35)

- Machinery (1)

- Made in California (7)

- Manufacturing Technology (3)

- Medical (1)

- Plastics and Rubber (1)

- Quality (27)

- Sales and Marketing (32)

- Smart Manufacturing (1)

- Supply Chain Management (1)

- Wood (1)