Challenge

Like many other manufacturers, Dramm & Echter, Inc. was presented with a major challenge: the economic downturn. The roadblocks appeared extremely difficult to overcome; a volatile market together with a staggering local economy and rising energy costs all led to struggles with profitability. Dramm and Echter decided that they couldn’t continue to do business the same way.

Their main goal was to increase their profit margins and they felt that improving efficiencies, reducing waste and boosting leadership effectiveness would help them to do this, as well as gain market share over the next several years. They decided to utilize the proven techniques and processes of Lean Manufacturing to help them achieve their goals. This included education, training, and hands on implementation in continuous improvement for all employees.

Solution

CMTC met with Bob Echter, President, to discuss how they could assist the company with achieving their vision and meet their desire to increase profit margins. Between October 2008 and September 2009 a series of in-depth training sessions took place at the company to look at their overall operations and to address training of their employees and managers. The first task was to conduct a business assessment to identify key areas of improvement. Training consisted of Lean Leadership Training, Quality Concepts Training, Lean Manufacturing Concepts and Simulation training. In addition,Value Stream Mapping of the green house and wholesale operations was completed, along with Kaizen Improvement events and Inventory Management Improvements. A Rewards and Recognition program was also developed for employees.The company received significant value in CMTC’s Change Management (CM) program, a process that is designed to help address organizational, behavioral and technical change simultaneously during implementing process improvements. The results of the CM program were that the management team and entire staff understood the importance of change and enthusiastically embraced it.

Improvement Description

After applying the tools and techniques the employees acquired during the training, the company realized both measurable and intangible benefits. Interdepartmental communication increased as all sectors of the company started working together on common goals. Product delivery times from the green house to refrigerated storage was reduced, quality improvements through improved handling and storage methods increased productivity by 15%, and annual labor costs decreased. This has resulted in increased profitability and long-term growth for Dramm & Echter, Inc.

Financial and Investment Impact

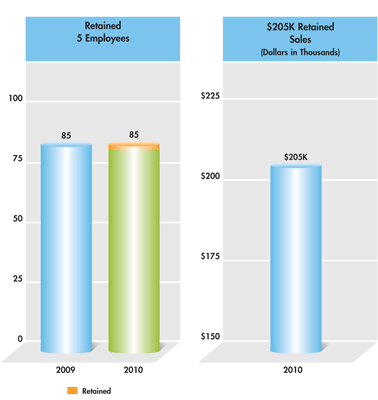

These improvements resulted in a $150,000 in annual cost savings. In addition, the company experienced improvements in quality, sales margins, and customer service. The company retained $205, 000 in sales and 5 employees as a result of the project.

"I’m glad we invested in CMTC during the downturn. It caused us to have a clear focus on improvement instead of concentrating on negativity. Understanding how important training is demonstrates your desire to improve the leadership and skills of your employees and the company as a whole."

Bob Echter

President

Case Studies

- Additive Manufacturing (3)

- Aerospace and Defense (14)

- Apparel (3)

- Business Growth Strategy & Strategic Planning (28)

- Continuous Improvement (8)

- Employee Training (14)

- Energy (7)

- Exporting (4)

- Farming (1)

- Food and Beverage (16)

- Fourth Industrial Revolution (24)

- Health & Safety Services (3)

- Industrial (1)

- Information Technology (3)

- Innovation & Growth (17)

- Lean (35)

- Machinery (1)

- Made in California (7)

- Manufacturing Technology (3)

- Medical (1)

- Plastics and Rubber (1)

- Quality (27)

- Sales and Marketing (32)

- Smart Manufacturing (1)

- Supply Chain Management (1)

- Wood (1)