Hill’s Pet Nutrition, a division of Colgate-Palmolive, has been operating in Los Angeles, California for over 20 years. Hill’s Pet Nutrition manufactures specialized dog food under its well recognized Science Diet brand. Hill’s Pet Nutrition customers include large retail chains in Japan and the United States. Hill’s Pet Nutrition has a diverse ethnic workforce of 90 employees responsible for approximately $24 million in annual revenue.

Challenge

Hill’s Pet Nutrition management’s goal was to reduce scrap and rework any associated energy costs. Hill’s Pet Nutrition determined the need to benchmark and ultimately improve its performance as compared to other Colgate-Palmolive production facilities located outside the state of California.Solution

In July 2005, CMTC consultants worked with Hill’s Pet Nutrition to establish their Strategic Energy Plan. An analysis was performed to identify areas of opportunity for improvement in manufacturing operations and energy management. In addition, an Energy Scorecard was established to evaluate baseline energy use, savings estimates and financial data and goals and measures. The Strategic Energy Plan was completed in August 2005.

Improvement Description

Prior to assessing energy use and implementing their Strategic Energy Plan, Hill’s Pet Nutrition had issues quantifying and prioritizing energy reduction opportunities. After implementing the Energy Scorecard and the Strategic Energy Plan, a quantified estimate of total savings from addressing energy improvement opportunities in the areas of set-up time, total productive maintenance, overall equipment effectiveness and waste reduction was developed. The plan was based on CMTC’s transformation planner benchmarking analysis. In addition, hardware related energy savings projects were identified based on the Department of Energy’s Industrial Assessment. Hill’s Pet Nutrition will track progress in the implementation of the Strategic Energy Plan and has established metrics including total energy cost for the facility, departments and process lines. They will measure electricity usage, cost and unit cost of production. Natural gas usage, cost and unit cost of production were also measured to determine results.

Financial and Investment Impact

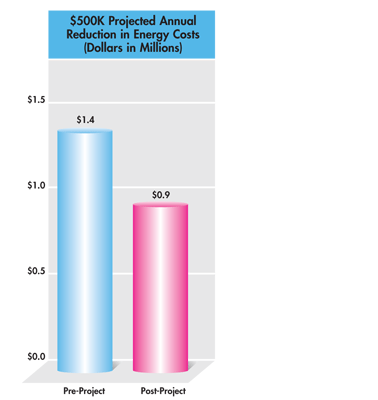

With the implementation of the Strategic Energy Plan, Hill’s Pet Nutrition identified approximately $500,000 of potential annual energy cost savings through process improvements.

“CMTC’s energy audit helped us identify and focus on big energy cost and usage areas. After working with CMTC, by improving our processes we found ways to save over $500,000.”

James Madison

Plant Manager

Case Studies

- Additive Manufacturing (3)

- Aerospace and Defense (14)

- Apparel (3)

- Business Growth Strategy & Strategic Planning (28)

- Continuous Improvement (8)

- Employee Training (14)

- Energy (7)

- Exporting (4)

- Farming (1)

- Food and Beverage (16)

- Fourth Industrial Revolution (24)

- Health & Safety Services (3)

- Industrial (1)

- Information Technology (3)

- Innovation & Growth (17)

- Lean (35)

- Machinery (1)

- Made in California (7)

- Manufacturing Technology (3)

- Medical (1)

- Plastics and Rubber (1)

- Quality (27)

- Sales and Marketing (32)

- Smart Manufacturing (1)

- Supply Chain Management (1)

- Wood (1)