Challenge

Jensen significantly expanded their current plans with starting a recycling program to reduce landfill costs and improve recycling, including sources for several items that were not recycled previously. It involved reducing hazardous chemicals in cleaning waste water along with related removal, handling, transport and disposal costs for the sludge. Jensen also decreased their energy costs.Solution

Jensen management elected to participate in the Green Supplier Network (GSN) program after considering the benefits because the Fontana facility is a key supplier to several California utility companies. The program included a site tour, mapping key manufacturing processes, environmental assessment, energy use evaluation and a benchmark report. CMTC observed facilities and production operations, interviewed key managers and requested information on energy use, production and waste streams. All departments developed a current state and potential future state of a Value Stream Map and completed an energy audit and environmental assessment.

The project resulted in 14 recommended improvement projects to improve environmental performance, increase competitiveness and profits, as well as several key energy and environmental recommendations.

"The savings were easy - once we knew what to do - and provided amazing return on investment."

Fred Franks General Manager Jensen Precast

Download This Case Study

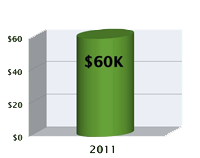

Projected Recycling

Program Savings Annually

(Dollars in Thousands)

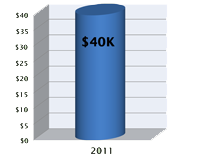

Projected Electrical

Energy Savings Annually

(Dollars in Thousands)

Financial & Productivity Results

- $60,000 transport and landfill cost savings

- $40,000 projected energy savings annually

Case Studies

- Additive Manufacturing (3)

- Aerospace and Defense (14)

- Apparel (3)

- Business Growth Strategy & Strategic Planning (28)

- Continuous Improvement (8)

- Employee Training (14)

- Energy (7)

- Exporting (4)

- Farming (1)

- Food and Beverage (16)

- Fourth Industrial Revolution (24)

- Health & Safety Services (3)

- Industrial (1)

- Information Technology (3)

- Innovation & Growth (17)

- Lean (35)

- Machinery (1)

- Made in California (7)

- Manufacturing Technology (3)

- Medical (1)

- Plastics and Rubber (1)

- Quality (27)

- Sales and Marketing (32)

- Smart Manufacturing (1)

- Supply Chain Management (1)

- Wood (1)