ProPlas Technologies is an innovative custom injection molding organization serving the healthcare, aerospace and defense, electronics, industrial, and commercial industries. The company offers full-service mold making capabilities from product design and prototyping, to production tooling, plus assembled and packaged products. ProPlas is based in Garden Grove, CA and employs 84 workers.

Challenge

ProPlas Technologies relocated in July 2014 to be closer to its customer base. As a result of the relocation, the organization suffered from a substantial loss of skilled workers. It was difficult to get new employees trained and the lack of job skills was leading to issues such as inefficiencies, errors during production, and rising scrap rates. Leadership also recognized that employee morale was low. The rising costs and production challenges were putting sales and jobs at risk, so ProPlas needed to make improvements.

Solution

ProPlas Technologies contacted CMTC in April 2015 regarding improving its Lean capabilities.

After the challenges were diagnosed and a foundation for continuous improvement was set, employees were trained on the fundamentals of Lean methodologies. Experts worked with ProPlas to establish more standardized processes on the production floor and focus on implementing process improvements. 5S training laid the groundwork for the improvement initiatives while coaching employees on how to prioritize safety practices and maintain those practices.

The training also focused on fostering communication between employees. Root cause analysis training helped leadership identify the main cause of problems and empowered leaders to work together and resolve conflicts. Formal communication meetings were also established to help bring team leaders together and rectify outstanding problems. Training concluded at the end of June 2015.

As a result of the improvements, ProPlas Technologies was able to successfully train their employees to embrace and implement Lean principles and reduce scrap rates and inefficiencies. Because the organization standardized processes and operated more efficiently, the company was able to become more productive and manage more demand.

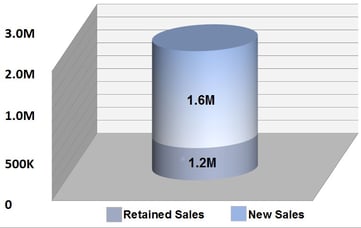

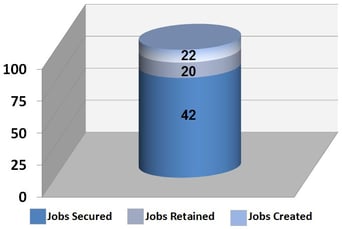

“Our organization was able to recognize $1.6 million in increased sales, $200,000 in cost savings, and 42 jobs created or retained through CMTC’s Lean Skills Consulting and Training.”

- Scott Taylor, President

Download This Case Study

$2.8M Total Sales

42 Jobs Created & Retained

Financial & Productivity Results

- $1.6M in new sales

- $1.2M in retained sales

- 22 jobs created

- 20 jobs retained

- $200K in cost savings

- $115K in capital investments

Case Studies

- Additive Manufacturing (3)

- Aerospace and Defense (14)

- Apparel (3)

- Business Growth Strategy & Strategic Planning (28)

- Continuous Improvement (8)

- Employee Training (14)

- Energy (7)

- Exporting (4)

- Farming (1)

- Food and Beverage (16)

- Fourth Industrial Revolution (24)

- Health & Safety Services (3)

- Industrial (1)

- Information Technology (3)

- Innovation & Growth (17)

- Lean (35)

- Machinery (1)

- Made in California (7)

- Manufacturing Technology (3)

- Medical (1)

- Plastics and Rubber (1)

- Quality (27)

- Sales and Marketing (32)

- Smart Manufacturing (1)

- Supply Chain Management (1)

- Wood (1)