RKL Technologies, Inc. is a contract machine shop which provides high precision metal parts for highly complex components and fixtures. Based in Corona, CA, it primarily serves the medical device industry, but also supports the aerospace and general industrial sectors. RKL has 34 employees and is ISO 9001:2008 & AS 9100, Rev. C certified.

Challenge

RKL Technologies was experiencing a downward trend in the medical device business segment. The company was losing customers to foreign competitors and was challenged to meet changing demands. RKL Technologies wanted to boost efficiencies and increase quality, reduce lead times, and more effectively meet the demands of its current customers and have the resources and capabilities to pursue and accept orders from additional companies and sectors.

Solution

RKL Technologies connected with CMTC. After assessing their needs, it was decided that the company would participate in a Lean for Growth consulting program. The goal was to train employees in the principles of Lean manufacturing, leverage Lean tools and take advantage of consulting to improve operations and create a more organized production process.

For five months, RKL Technologies’ employees participated in multiple Lean training sessions. Team members worked with CMTC to discover the main causes for disruptions and developed solutions to implement. For example, a rapid improvement (Kaizen) event was conducted to quickly identify small, incremental changes in their processes to boost efficiencies.

Improvements such as a new documentation process helped employees to collaborate and foster communication. They also reorganized the equipment on the facility’s floor to create a more logical flow of production that enabled them to discover disruptions and issues earlier in the production process. The implemented changes allowed RKL Technologies to reduce lead times, improve quality to better meet customer requirements, and position themselves for future growth.

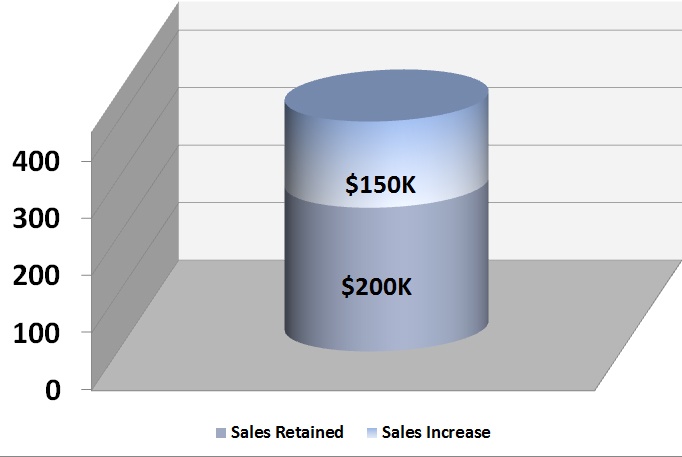

“CMTC’s assistance enabled our organization to improve efficiencies, reduce lead times and better meet customer demand. This allowed us to become more competitive, resulting in $150,000 in increased sales, $200,000 in retained sales and $60,000 in cost savings.”

- Roy Hornstein, President

Download This Case Study

$350K Total Sales Impact

(Dollars in Thousands)

Financial & Productivity Results

- $150K in new sales

- $200K in retained sales

- $60K in cost savings

- 6 new jobs created

- 12 jobs retained

- $155K in new investments

Case Studies

- Additive Manufacturing (3)

- Aerospace and Defense (14)

- Apparel (3)

- Business Growth Strategy & Strategic Planning (28)

- Continuous Improvement (8)

- Employee Training (14)

- Energy (7)

- Exporting (4)

- Farming (1)

- Food and Beverage (16)

- Fourth Industrial Revolution (24)

- Health & Safety Services (3)

- Industrial (1)

- Information Technology (3)

- Innovation & Growth (17)

- Lean (35)

- Machinery (1)

- Made in California (7)

- Manufacturing Technology (3)

- Medical (1)

- Plastics and Rubber (1)

- Quality (27)

- Sales and Marketing (32)

- Smart Manufacturing (1)

- Supply Chain Management (1)

- Wood (1)