Challenge

Royal Truck Body management determined a need to implement process improvements in its Paint Department to improve painting quality and to gain higher efficiencies. Royal Truck Body and CMTC agreed that Lean manufacturing principles were needed to improve process workflow and increase work quality and yield of finished units. The team also sought to use Lean manufacturing techniques to reduce costs and thereby help Royal Truck Body in improving its competitive advantage.Solution

Implementation Highlights

The project began in September 2006 and ended in October 2006. A process improvement event (Kaizen) methodology was facilitated by CMTC in Lean manufacturing techniques in the paint shop supported by classroom training for 15 Royal Truck Body employees. CMTC consultants first developed a value stream map to analyze the current state, then a future state map to identify areas for improvement. These areas included quality, safety and process redesign. In addition, 5S (Sort, Set in Order, Shine, Standardize and Sustain) was used to organize the paint shop.

Improvement Description

The project resulted in several improvements in the paint shop. Labor productivity was improved from 19.6 hours per unit to 10.8 hours per unit. Work in progress units decreased from 70 to 18 units requiring fewer raw materials. Lead times were reduced from 5 days to 1⁄2 day resulting in additional capacity that was used to support new customers. Implementing 5S principles in the paint shop improved cleanliness and safety resulting in higher product quality.

Financial and Investment Impact

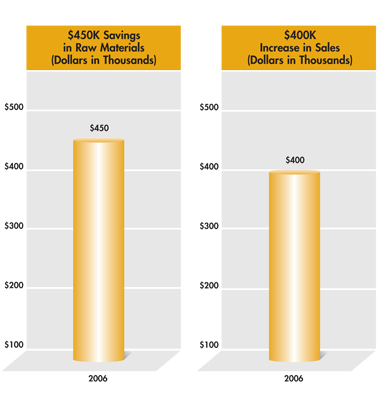

The increase in productivity and subsequent reduction in raw materials to support work in progress resulted in savings of $450,000. The reduction in lead times resulted in additional capacity to support an increase in demand. As a result, sales increased by $400,000 per year

"CMTC was instrumental in helping us meet our increased demand for quality products."

Joe Valdiva

President

Case Studies

- Additive Manufacturing (3)

- Aerospace and Defense (14)

- Apparel (3)

- Business Growth Strategy & Strategic Planning (28)

- Continuous Improvement (8)

- Employee Training (14)

- Energy (7)

- Exporting (4)

- Farming (1)

- Food and Beverage (16)

- Fourth Industrial Revolution (24)

- Health & Safety Services (3)

- Industrial (1)

- Information Technology (3)

- Innovation & Growth (17)

- Lean (35)

- Machinery (1)

- Made in California (7)

- Manufacturing Technology (3)

- Medical (1)

- Plastics and Rubber (1)

- Quality (27)

- Sales and Marketing (32)

- Smart Manufacturing (1)

- Supply Chain Management (1)

- Wood (1)