Challenge

Trojan’s Management wanted to stay in California and increase their competitiveness. The company’s goal was to improve battery assembly production to meet growing demand. To accomplish this goal, Trojan management recognized a need to improve key production processes and reduce cost per unit.Solution

Project objectives included increasing assembly throughput bystandardizing processes and organizing the key constraint point, the ”Post Burning” assembly operations. CMTC® assisted in streamlining manual processes that produced the posts for each battery. The processes were mapped to determine a more fluid flow. Prior to implementing the improved process flow, a comprehensive training program was implemented on Lean manufacturing principles to prepare employees to properly implement and sustain project improvements. Following the training program, several improvements were made to systematically implement the new processes. The project began in March 2006 and was completed in approximately three months.

Improvement Description

The manual processes were streamlined by improving the layout of the work area and reducing walk and wait time. As a result, the lead melting and battery post forming processes were made more efficient -- providing a 33% increase in productivity. The Post Burning assembly operation increased productivity from 2,730 to 3,640 batteries per shift.

Financial and Investment Impact

Following project implementation, Trojan Battery recognized a production increase of 900 batteries per shift and a reduction in costs of $218,000.

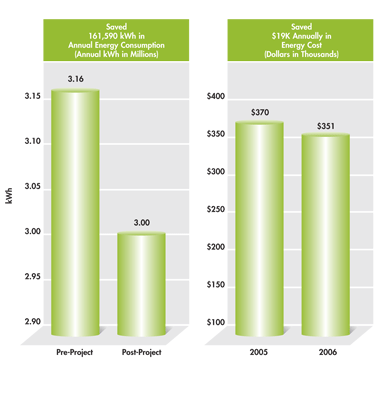

“With CMTC’s consulting support, we saved 1,283,639 annual kilowatt hours for the same amount of production. We are on our way to reducing our energy costs by $1,000,000 per year.”

Chad Bentley

Manager Manufacturing Technology

Case Studies

- Additive Manufacturing (3)

- Aerospace and Defense (14)

- Apparel (3)

- Business Growth Strategy & Strategic Planning (28)

- Continuous Improvement (8)

- Employee Training (14)

- Energy (7)

- Exporting (4)

- Farming (1)

- Food and Beverage (16)

- Fourth Industrial Revolution (24)

- Health & Safety Services (3)

- Industrial (1)

- Information Technology (3)

- Innovation & Growth (17)

- Lean (35)

- Machinery (1)

- Made in California (7)

- Manufacturing Technology (3)

- Medical (1)

- Plastics and Rubber (1)

- Quality (27)

- Sales and Marketing (32)

- Smart Manufacturing (1)

- Supply Chain Management (1)

- Wood (1)