May 25, 2021 | Additive Manufacturing

Your Go-To-Guide to Identifying if Additive Manufacturing is Right for You

Additive Manufacturing, also known as 3D printing, has gone from a futuristic novelty to a widely available technology. Even though additive manufacturing has been around since the mid1980’s, the growth in use and commercialization of the technology has exploded in the last five years. Printers have gotten faster, cheaper, and more compact, not to mention the ever-growing selection of plastic and metal materials.

Additive manufacturing breaks the limits of traditional methods by changing the way the production parts are created and supported. When applied to the right situations, additive manufacturing can deliver products with greater efficiency and improved performance. The advantages don’t stop there, though; there are a wealth of financial advantages to 3D printing, ranging from reduced product waste to lower cost for complex parts to revenue opportunities on small quantity production.

This comprehensive guide covers a depth of information regarding additive manufacturing, its benefits, what to consider when getting started, and more!

Quick Links

- What is Additive Manufacturing?

- 6 Benefits of Leveraging Additive Manufacturing in Your Manufacturing Facility

- Is Additive Manufacturing Right for Your Company? 5 Considerations to Make Before Implementing This Manufacturing Technology

- Maximize Your Investment in Additive Manufacturing With CMTC!

What is Additive Manufacturing?

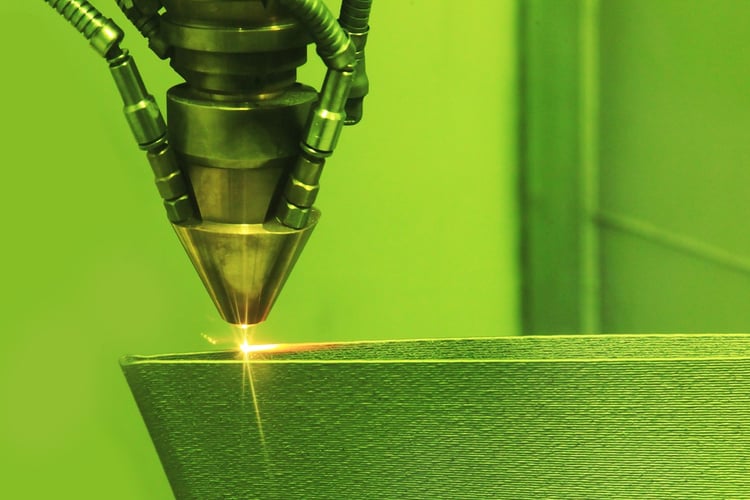

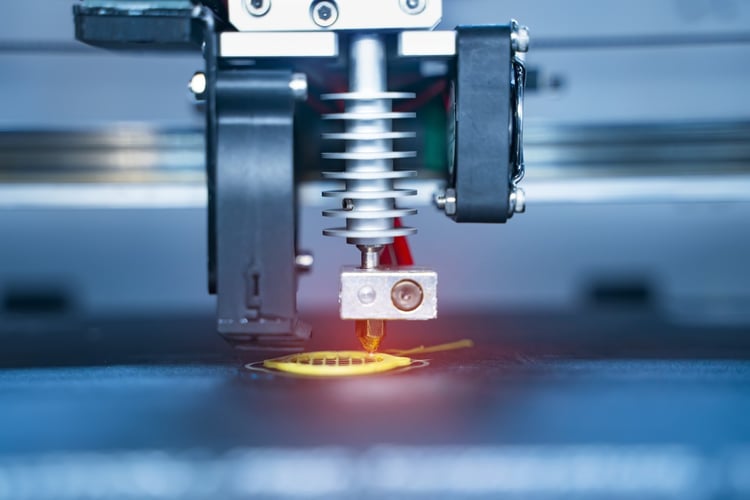

Additive manufacturing, or 3D printing, is a process that creates a tangible object from a digital design. While a traditional 2D printer uses a computer to read a file and print out a flat, two-dimensional replica on fabric or paper, 3D printing creates a physical object from a digital file, utilizing layer after layer of material, until it forms a completed three-dimensional object.

Additive manufacturing technologies build three-dimensional objects one fine layer at a time. Each subsequent layer bonds to the preceding later of partially melted material. In other words, instead of removing material during the production process to make part features such as holes, the part would be constructed using additive manufacturing methods with the hole already formed in the finished part.

The layering material can be almost any type of substance, ranging from metal powder, ceramics, thermoplastics, glass - even chocolate! As a result, 3D printers are not one-size-fit-all; there are a variety of options for 3D printing, thus the type of printer ranges for different applications.

Additive manufacturing has been used to build physical models, prototypes, tooling components, and production parts in a variety of media, including metal, plastic, and composite materials. Almost any shape can be replicated on a 3D printer, and parts can be manufactured in a variety of colors and even with more than one material.

6 Benefits of Leveraging Additive Manufacturing in Your Manufacturing Facility

3D printing has been heralded for its innovative industrial manufacturing abilities. There are several advantages that make this manufacturing technology a valuable asset championed by companies around the world, including:

Reduced Development Costs

This advanced manufacturing technology has the stereotype of being somewhat pricey, due to its initial cost. However, the long-term reduced development costs yield money-saving benefits.

In terms of machine operation costs, it depends on the size of the 3D printer. Most desktop 3D printers use as much power as a laptop, while some large industrial 3D printers use a significantly larger amount. Still, their ability to produce complex objects in a single step results in greater efficiency and productivity.

One of the main advantages of 3D printing is the reduced cost of labor. Besides post-processing, most printers are self-sufficient and barely need assistance from an operator. The labor costs for a 3D printer are essentially nonexistent, compared to traditional manufacturing where highly skilled operators are usually necessities.

Additionally, additive manufacturing at low volumes is competitive in cost compared to traditional manufacturing. It is significantly less expensive to 3D print prototypes rather than with other manufacturing methods, such as injection molding, traditional dies, molds, milling, and machining.

Less Product Waste

By designing drafts in a computer program and then sending them to be printed, the time to create and produce new designs is drastically shortened with less waste. This digital-to-digital process removes the additional intermediate steps of traditional prototyping.

Additionally, 3D printing has increased turnaround. With the ability to create quick iterations, 3D printing identifies engineering and design issues that may have taken weeks, if not months, to discover in traditional manufacturing.

Additive manufacturing enables the creation of complex designs that are normally too difficult or too expensive to build. Process development can be accomplished in less time with money spent on designing and building prototypes with traditional methods, such as molds and dies. There is also less product waste from the need to scrap molds for parts and features that have changed in prototype iterations.

Decisions on final part designs can be achieved faster because the time required for effective design and creation is reduced. Overall, additive manufacturing offers a more effective and efficient design process with less waste and reduced spending.

Improved Quality of Products

The advantages of 3D printing extend into providing better quality product design and process development. Additive manufacturing allows manufacturers to create superior products because design issues, such as bad ergonomics, can be identified early and resolved swiftly. As a result, the quality of the parts can be improved with a better final design with 3D printing.

Furthermore, this technological advancement allows engineers to build complex and intricate parts that are not cost-effective or even possible with typical manufacturing methods. Engineers are no longer restricted to the limitations of traditional equipment; some parts that were designed as assemblies requiring joining, fastening, or welding can be printed as a single part. This reduces waste while often adding greater strength and durability to the product and reduces the potential points of failure.

3D printing can also create parts out of a variety of different substances, such as thermoplastics. Some of these materials can substantially reduce weight while still maintaining strength and integrity. This is exceptionally helpful when engineers want to maintain strength but reduce weight.

Additive manufacturing can be a valuable technology to create durable products that can maintain continuous use due to their improved quality.

Genuinely Rapid Prototyping

Do you remember when “rapid” prototyping meant a lead-time of weeks or months to design and manufacture? This was primarily due to the need to manufacture a prototype tool or fixture and probably outsource a portion of this work, as many manufacturers focused on production, but didn’t want to tie up valuable time to produce a singular prototype part.

With additive manufacturing, you can design and produce a prototype on a 3D printer in hours - not weeks! Instead of designing for manufacturing, you can now manufacture for design. In addition, parts can be produced to specifically meet complex customer specifications. This is a game-changer for prototyping.

What does this mean for your company? With a relatively small investment in a 3D printer and expertise, you can now quickly produce mock-ups of a new product and have it in the customer’s hands in a matter of days. Plus, you can produce a part to meet a very specific market niche, which could lead to the production of high-profit margin products.

A Means to Attract Talent, Expertise, and Enthusiasm to Your Company

In the second article in our blog post series on attracting those from the millennial generation, “How to Attract Millennials and Preserve the Future of Manufacturing” we discussed the incorporation of additive manufacturing and other new technologies into your workplace to attract skilled workers from this population. As stated in that article, you can use additive manufacturing equipment to attract young, skilled workers to your facility.

Is Additive Manufacturing Right for Your Company? 5 Considerations to Make Before Implementing This Manufacturing Technology

As with the implementation of any substantial change in your manufacturing process, there are several factors to consider and explore before bringing new technology into your company.

Recognize the Mindset Change Associated With Additive Manufacturing

While additive manufacturing is a powerful tool for manufacturers, the effective use of additive manufacturing requires a change in mindset for design engineers and company managers. Additive manufacturing goes against many of the principles that most design, mechanical, and industrial engineers learn in school.

For example, traditionally, sheets of metal have traditionally been used as raw material for a metal fabrication process. These sheets are laser cut to produce a shape. The job of design engineers has been to order the right size of steel sheet and design the program to optimize the nesting of parts within that sheet to minimize scrap. The less steel taken away, the lower the scrap costs, and the higher the profits.

In the case of additive manufacturing, rather than focus on reducing the amount of material removed from a process, you build a product up, adding material where needed or taking it away in the design phase to produce a part. So, instead of cutting a shape out of a sheet of steel, you build up the same part using a 3D printer. If you don’t like the shape or features, simply change the model and print another one! Once you have a design that you like, you can print off as many copies as you need.

As you can see, the design mindset is flipped on its head when additive manufacturing is involved. The considerations shift from reducing the amount of material taken away to optimizing the part design and then building a part, one by one.

Here are some simple and relatively inexpensive ways to retrain your design engineers to work with 3D printing technologies:

Learn

Many universities and community colleges have developed additive manufacturing programs. These can range from degree specializations and certificate programs to additive manufacturing workshops and seminars. Additive manufacturing events also provide opportunities for engineers and company managers to learn more about the technology, which is critical for any significant process change.

Read

Magazines, such as Make Magazine, are published to showcase examples of 3D materials and provide comparisons between printer models so you can select the right one for your company. The internet also contains a wealth of data on additive manufacturing and 3D printing. Our website has an entire section devoted to additive manufacturing information and resources.

Network

Ask around and connect with local manufacturers who are using 3D printing. Learn how they utilize its features and optimize its capabilities. Manufacturers networks, the local chamber of commerce, and events are places where you may be able to find others using the technology.

Experiment

The cost of personal and desktop 3D printers has gone down dramatically as more models are introduced and competition increases in this market. A desktop mini-printer can be purchased for as little as $500. If you are considering incorporating additive manufacturing into your operations, purchase one or a few and provide them to your engineers, as Ford Motor Company does. There is no better way to learn about the technology and change the mindset than by letting the designers and engineers play with the technology. Once the capabilities of Additive are better understood by your designers and engineers, identifying the right industrial-grade Additive technology for your company’s needs will be far easier.

New technologies can be scary, but they can also be exciting! The promise of additive manufacturing in the next five years is thrilling, from the production of custom, functioning prostheses to the use of 3D printing in the majority of elementary school classrooms and homes.

Maximize Your Investment in Additive Manufacturing with CMTC!

What if you don’t know how to use a 3D printer? When additive manufacturing first came to the market, there were only a few resources to assist manufacturers in using the technology, and those that existed tended to be very expensive. There are other free or inexpensive ways to acquaint your company with additive technology and possible applications to your situation. CMTC sponsors additive manufacturing webinars, which include presentations from experts and resources in the field of additive manufacturing.

As the demand for customized parts continues to rise, additive manufacturing processes will continue to become more and more relevant in the future. AM equipment manufacturers are predicting that as more companies begin to adopt these technologies, it is only a matter of time before the future of manufacturing is completely transformed.

CMTC recognizes the importance of this path forward and is here to help you transform your manufacturing company with additive manufacturing. Contact us to learn more!

About the Author

Gregg Profozich

Gregg Profozich is a manufacturing, operations and technology executive who believes that manufacturing is the key creator of wealth in the economy and that a strong manufacturing sector is critical to our nation’s prosperity and security now, and for future generations. Across his 20-year plus career in manufacturing, operations and technology consulting, Mr. Profozich helped manufacturing companies from the Fortune 500 to the small, independents significantly improve their productivity and competitiveness.