August 7, 2013 | Supply Chain Management

The Optimized High Performing Supply Chain

|

Written by: Terry Weiner The following post is #3 of a series and focuses on the optimized high performing supply chain. This series of posts will provide an overview of the Supply Chain Optimization process and preview some of the concepts and tools that are part of the Manufacturing Extension Partnership (MEP) Supply Chain Optimization Initiative. Click here to read earlier posts. |

|

The Optimized High Performing Supply Chain

The Optimized High Performing Supply Chain

Our optimization activities need to employ System Thinking. We need to focus on improving the performance of the supply chain, but also focus on the supply chain’s business objective to support the organization’s business strategy.

improving the performance of the supply chain, but also focus on the supply chain’s business objective to support the organization’s business strategy.

- Seek to develop partnerships and alliances with members of the supply chain strategically, with the goal of delivering goods and services as quickly and efficiently as possible.

- Use forecasts to plan and pull to execute. A system that reacts to pull signals will have less variation than a comparable system that adopts a push mode of operation.

- Reduce variation in the system. Reduced variation allows the supply chain to operate with higher throughput, lower investment, and lower operating expense.

The optimized solution is based on the prediction of the future constraint(s), the exploitation and subordination of both the current and future constraints, and the ability to successfully implement the control measures to validate the planning assumptions.

To perform best, now and in the future, we need to know the internal limitations of the system. Tactics should concentrate on the actual exploitation of the existing constraint(s), and the synchronized plan for key non-constraints (subordination).

We also need to provide some excess capacity at the constraint, to preserve our flexibility to respond to changing market requirements.

Getting It All to Work Together

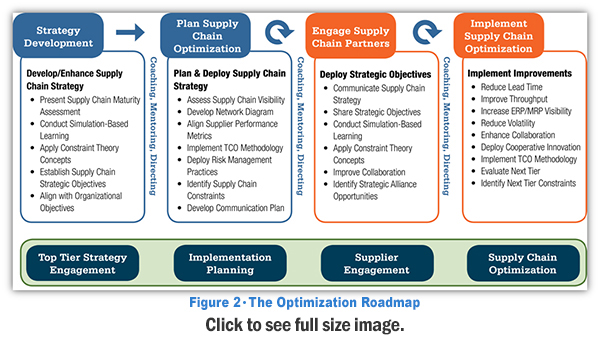

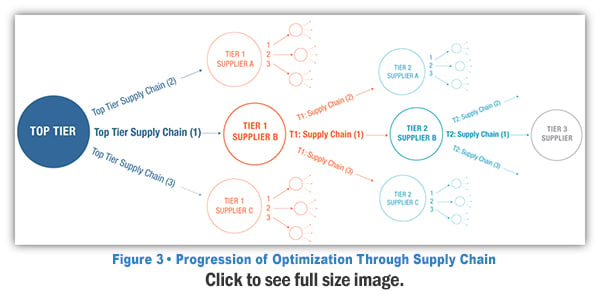

The Manufacturing Extension Partnership (MEP) Supply Chain Optimization Initiative employs an engagement methodology that begins with the top tier, a supply chain maturity assessment, and a Strategy Development session.

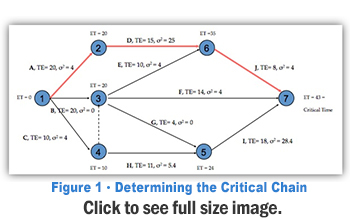

During the Strategy Development session, the Supply Chain Strategy and Implementation Game Plan are developed. The supply chain is mapped and a critical chain analysis of the supply chain is done to identify those supply chain partners who will be engaged and in what sequence.

During the Strategy Development session, the Supply Chain Strategy and Implementation Game Plan are developed. The supply chain is mapped and a critical chain analysis of the supply chain is done to identify those supply chain partners who will be engaged and in what sequence.

Supply chain risks are examined and a risk management plan is developed. The mitigation costs are then transferred to the Total Cost of Ownership (TCO) analysis.

The concept of using TCO in making strategic sourcing decisions is reviewed in the TCO Overview session. A TCO Calculator is provided to do side-by-side comparisons of suppliers under consideration. The calculator can also be used to estimate the impact of various “what-if” scenarios. These scenarios can be employed to evaluate the effect of various improvement strategies on future TCO.

Details of the Strategy Development and other optimization activities will be the subject of future articles, so we won’t go into too much detail here.

The supply chain strategy is discussed in meetings with suppliers who are on the supply chain critical path. The actions needed to develop the throughput and capacity to meet current and future customer demand is planned.

What's Next?

In future posts, we will look at the following components of the Supply Chain Optimization Initiative - Link by Link:

Terry Weiner is a Senior Consultant with California Manufacturing Technology Consulting® (CMTC). He has over 20 years experience in process improvements, quality management implementation and supply chain optimization.